-

ORGANIC AGRICULTURE

- AGROBIOFILM

- RECTIFIER VACUUM CLEANER

- DISPOSABLE PLASTIC BOX

- HARVESTERS FOR AROMATIC AND MEDICINAL PLANTS

- UNWINDER WATERING TAPE

- MANUAL. SEEDER

- HYBRID SOLAR DRYERS FOR AROMATIC PLANTS AND FOOD

- MULTI-SEED MECHANICAL SEWER.

- BIG GRAIN SEEDER

- HEATING SYSTEMS FOR INDUSTRIAL WAREHOUSES

- SYSTEM FOR COLLECTING PARSLEY

-

ENVIRONMENT

- RAINWATER

- RETENTION BASINS

- SANITARY BOOTHS

- BATTERY CASES

- SAMPLING BOX

- SCREENING BOX

- TANKS FOR INDUSTRIAL CLEANING

- TOOLS BOX

- SELECTIVE COLLECTION CONTAINER

- TANKS WITH LIDS DCT

- DOSING TANKS DSD

- HORIZONTAL TANKS DHE

- HORIZONTAIS TANKS DHS

- VERTICAL TANKS DVA/DVB/DVBR

- ECOFLO-COCONUT COMPACT FILTER

- ECOIL-USED OILS TANKS

- ECOPROCESS TM

- PUMPING STATIONS

- SEPTIC TANKS MILENIUM

- COMPACT SEPTIC TANKS

- SIMPLE SEPTIC TANKS

- MICRO-ETAR SOLIDO SMART

- BEACH CLEANING MACHINE

- GREASE SEPARATOR

- HYDROCARBON SEPARATORS

- SUPERFUSTO

- DRUM SUPPORT

- INDUSTRIAL SCALE

- PUMPS FOR FUELS

- CONTENTOR - OFICINA

- DIESEL DEPOSIT

- WEEDING THERMAL ECO

- WASHING EQUIPMENT

- FORAGER EQUIPMENT

- FRUTICULTURE

- DRY FRUITS

- GPS AGRICOLAS

-

HORTICULTURE

- FERTILIZER LOCATOR

- BED FORMER AND PLASTIC FIXER

- ROTATING CULTIVATOR

- POTATO DIGGERS

- RECTIFIER VACUUM CLEANER.

- POTATOS LOADER

- CARROT HARVESTER

- ONION LOADER

- CITRUS HARVESTER

- DISPOSABLE PLASTIC BOX..

- VEGETABLE HARVESTER DI PIETRI

- VEGETABLE HARVESTERS ORTOMEC

- VEGETABLES HARVESTER

- GARLIC CULTURE

- PLASTIC DISPENSERS MACHINE

- SOIL DISINFECTION BY STEAM

- FURROW OPENER

- KITAPE

- FLAME WEEDING

- MULTIFRAS

- POTATO PLANTER

- PRE-BED FORMER

- MACHINE FOR COLLECTION IRRIGATION HOSE

- RECOLHEDORA DE PLÁSTICO AGRICOLA

- AUTOMATIC HOE

- WEEDING MACHINES

- SYSTEM FOR COLLECTING PARSLEY.

- TRANSPLANTERS

- SIDE CONVEYOR BELT

- MOBILIZATION OF SOIL

- LIVESTOCK

- POLISHER

- SPRAYERS

- SOWING

-

FORESTRY

- ANGLODOZERS

- GARDEN VACUUM CLEANERS

- HEDGE MOWING BAR

- BIOSHREDDERS

- BULDOZERS

- HYDRAULIC HEADS

- ROTARY CUTTERS

- LAWN MOWER

- BULLRING CUTTER

- TRIMMER

- FURROW OPENER RIENFORCED.

- MOUND MACHINE FOR ORCHARDS.

- DISC HARROWS V-TYPE

- FORESTRY WINCHES

- POST HOLE DIGGER

- TOOL HOLDERS ER

- SHOVEL GRADERS

- PRUNERS FOR ORCHARDS

- RIPPERS

- BRUSH CUTTERS

- WOOD-SPLITTERS

- BLADE ROLLER.

- ROTARY TILLERS BY RADIO CONTROL

- HYDRAULIC ARM IRONER

- TRACTOR BACKHOE

- SHREDDERS AGRIMASTER

- ROTARY TILLERS JOPER.

- FORESTRY SHREDDERS

- CRUSHERS RINIERI

- ROTARY TILLERS HERKULIS

- CRUSHERS FOR BIOMASS

- STONE MILLS

- STRAINERS SERRAT LATERALS

- VINEYARDS REMAINS FROM PRUNING

- CRUSHERS SERRAT

- IRRIGATION SYSTEMS

- AGRO CONTROL SYSTEMS

- SCISSORS FOR PRUNING.

- TRANSPORT

- FLORICULTURAL NURSING

-

GRAPE VINE

- BOXES STAINLESS FOR GRAPE

- PLASTIC BOXES STACKABLE

- ELECTRICAL TROLLEY

- WIRE UNWINDERS

- FEEDING BUCKET

- MANURE SPREADERS

- VINEYARD DISC HARROWS

- OFFSET MACHINERY

- ELECTRIC TYING MACHINE FOR GRAPEVINE

- HITTING STAKES HAMMER

- POST HOLE DIGGER.

- ROLLER HARROW VINEYARD

- TOWING OF INOX FOR GRAPE.

- SCISSORS FOR PRUNING

- VINE AND TREES PLANTER

- TOWED VINDILLER

- PRUNING REST CRUSHER

- CHISEL VINHATEIRO

- SPARE PARTS

- USED MACHINES

- ABBRIATA

- ABRIMEC

- AGRATOR

- AGRICOLA ITALIANA

- AGRIMASTER

- AGROBIOFILM

- AGROGUIA

- AGROOP

- AGROTECH

- AMB ROUSSET

- ARGILES

- ASPLA

- BARGAM

- BBKW

- BONDIOLI & PAVESI

- BONINO

- CACHAPUZ

- CAEB

- CARLOTTI G. & C. S.N.C.

- CECCATO OLINDO

- CETAP

- CHECCHI & MAGLI

- CITERGAZ

- COMEB

- D'EUSANIO

- DAGNAUD

- DI PIETRI

- DONDI

- EAZYCUT

- ENOROSSI

- ENRIA

- F. LLi. ANNOVI

- FAE

- FARDIN

- FELCO

- FERRARI

- FEUCHT - OBSTTECHNIK

- FIALHO

- FIMAKS

- FMP

- Farmi

- GARRIGA

- GASPARDO

- GIAMPI

- GUARESI

- HERKULIS

- HYMACH

- ID-DAVID

- IMAC

- IRRILAND

- J.J.BROCH

- JB INDUSTRIE

- JOPER

- M.MARTI

- MAIA

- MAMMUT

- MARTIGNANI

- MM SPRAY

- MOSA GREEN

- MTS.SANDEI

- NASI

- OLITREE

- OLIVERAGRO

- OMARV

- ORTOMEC

- PAGLIARI

- PELLENC

- PIRODISERBO

- PIUSI

- POMI

- PREMIER TECH

- R.A.P

- REBOAL

- RIBATEJO

- RINIERI

- ROCHE

- SERRAT

- SIMON

- SIMOX

- TAREX

- TATU

- TERRADONIS

- TERRATECK

- TEYME

- TOMENZOLI

- TOMIX

- TOUPEIRA

- TRIMBLE

- VALENTINI

- WAGNER

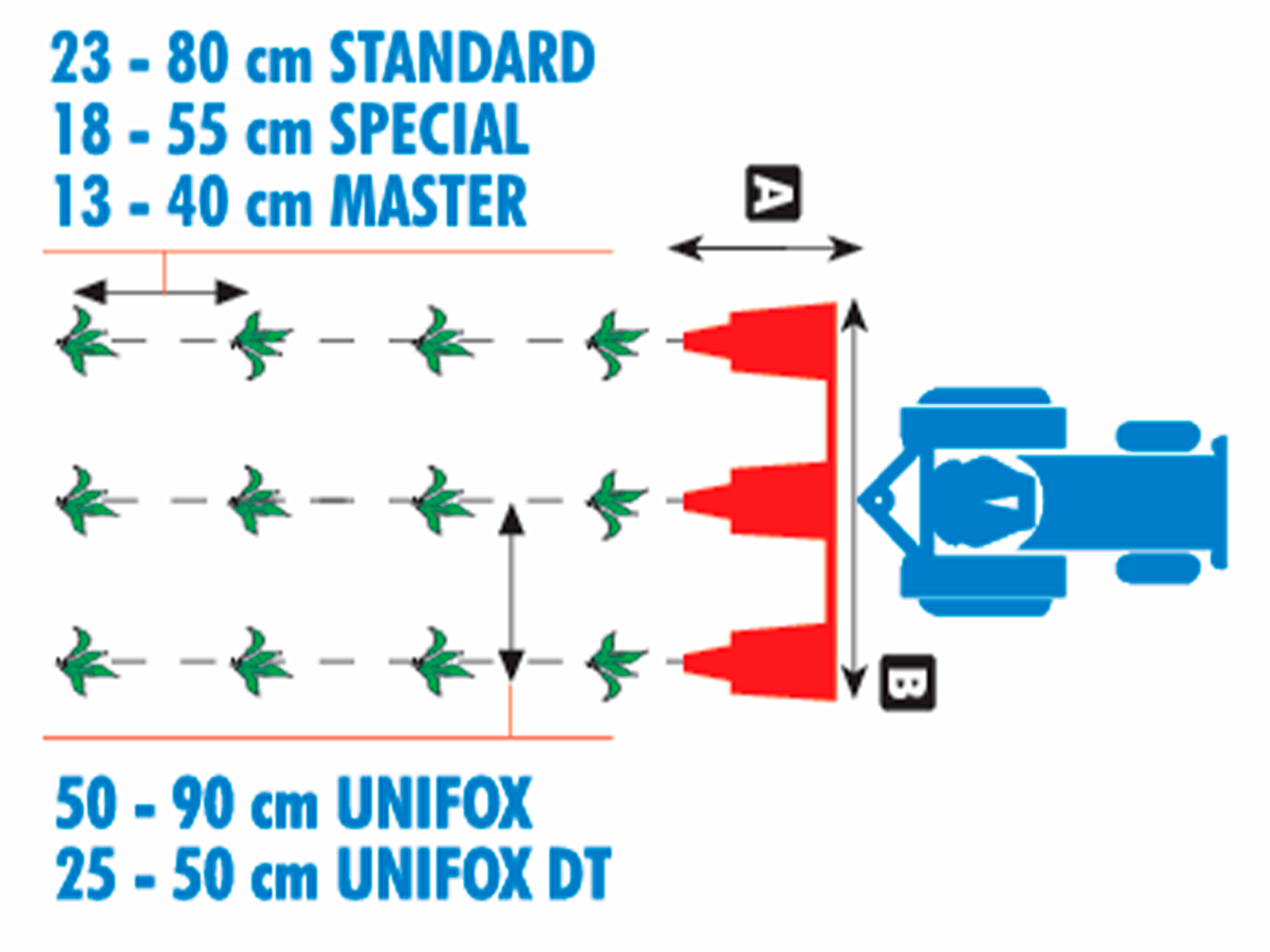

TRANSPLANTER CHECCHI & MAGLI UNIFOX

-

Categories::

-

Brands:CHECCHI & MAGLI

- Available by order

-

SKU::UNIFOX

CHECCHI & MAGLI UNIFOX

🌱 The transplanter that adapts to every need

Versatile, efficient and ready for any type of seedling, this machine works with bare‑root plants or peat plugs in conical, pyramidal or cubic shapes. Its flexibility makes it a true universal transplanter, capable of meeting the demands of different crops and production methods.

👨🌾 Easy to use, even for inexperienced operators Its intuitive design allows fast and efficient operation, reducing training time and boosting productivity from day one.

🚜 Precision and consistency in every planting Each transplanting unit features an independent drive wheel, ensuring constant traction while leaving the compaction wheels free to create a perfect ridge. The result is a planting spacing that is always precise, uniform and adjustable, even under demanding working conditions.

Versatile, robust and fully configurable transplanter

The perfect solution for those seeking efficiency, precision and adaptability in agricultural transplanting. Designed to meet the needs of both small and large producers, this machine offers multiple configurations that ensure superior performance on any type of terrain.

🔧 Customisable Configuration for Every Crop

Available distributors:

-

Standard (10 clamps) – plant spacing from 23 to 80 cm

-

SPECIAL (15 clamps) – optional, ideal for higher density, 18 to 55 cm

-

MASTER (20 clamps) – optional, maximum productivity, 13 to 40 cm

💺 Comfort for Long Working Days

-

Standard reinforced plastic seat

-

Optional: padded ergonomic seat

🚜 Superior Performance on All Terrains

-

Standard iron compaction wheels

-

Optional: flexible rubber wheels, ideal for wet or clay soils

🛠️ Robust and Precise Construction

-

Reinforced wear‑resistant ploughshare with depth adjustment

-

Independent and oscillating front drive wheel for each transplanting unit

-

Adjustable pressure spring for perfect soil ridging

🌿 Productivity‑Boosting Accessories

-

Optional: clod separator

-

Standard plant box for bare‑root seedlings

-

Optional: maxi plant box for large quantities

-

Optional: rotating tray holder for plug seedlings

A) Standard distributor • 10 clamps, plant spacing 23–80 cm Optional: SPECIAL distributor with 15 clamps, plant spacing 18–55 cm Optional: MASTER distributor with 20 clamps, plant spacing 13–40 cm

B) Standard reinforced plastic seat Optional: special padded seat

C) Standard iron compaction wheels Optional: flexible rubber compaction wheels for wet and clay soils

D) Reinforced wear‑resistant ploughshare with depth adjustment

E) Independent and oscillating front drive wheel for each transplanting unit

F) Pressure spring to increase or decrease the weight on the compaction wheels, ensuring ideal ridging

G) Optional: clod separator

H) Standard plant box for bare‑root seedlings Optional: maxi plant box for large quantities of bare‑root seedlings Optional: rotating tray holder for plug seedlings