storefront::account.login

storefront::account.dont_have_an_account

storefront::account.create_account

storefront::account.reset_password

storefront::account.register

storefront::account.back_to_login

Menu

Categories

Brands

-

ORGANIC AGRICULTURE

- AGROBIOFILM

- RECTIFIER VACUUM CLEANER

- DISPOSABLE PLASTIC BOX

- HARVESTERS FOR AROMATIC AND MEDICINAL PLANTS

- UNWINDER WATERING TAPE

- MANUAL. SEEDER

- HYBRID SOLAR DRYERS FOR AROMATIC PLANTS AND FOOD

- MULTI-SEED MECHANICAL SEWER.

- BIG GRAIN SEEDER

- HEATING SYSTEMS FOR INDUSTRIAL WAREHOUSES

- SYSTEM FOR COLLECTING PARSLEY

-

ENVIRONMENT

- RAINWATER

- RETENTION BASINS

- SANITARY BOOTHS

- BATTERY CASES

- SAMPLING BOX

- SCREENING BOX

- TANKS FOR INDUSTRIAL CLEANING

- TOOLS BOX

- SELECTIVE COLLECTION CONTAINER

- TANKS WITH LIDS DCT

- DOSING TANKS DSD

- HORIZONTAL TANKS DHE

- HORIZONTAIS TANKS DHS

- VERTICAL TANKS DVA/DVB/DVBR

- ECOFLO-COCONUT COMPACT FILTER

- ECOIL-USED OILS TANKS

- ECOPROCESS TM

- PUMPING STATIONS

- SEPTIC TANKS MILENIUM

- COMPACT SEPTIC TANKS

- SIMPLE SEPTIC TANKS

- MICRO-ETAR SOLIDO SMART

- BEACH CLEANING MACHINE

- GREASE SEPARATOR

- HYDROCARBON SEPARATORS

- SUPERFUSTO

- DRUM SUPPORT

- INDUSTRIAL SCALE

- PUMPS FOR FUELS

- CONTENTOR - OFICINA

- DIESEL DEPOSIT

- WEEDING THERMAL ECO

- WASHING EQUIPMENT

- FORAGER EQUIPMENT

- FRUTICULTURE

- DRY FRUITS

- GPS AGRICOLAS

-

HORTICULTURE

- FERTILIZER LOCATOR

- BED FORMER AND PLASTIC FIXER

- ROTATING CULTIVATOR

- POTATO DIGGERS

- RECTIFIER VACUUM CLEANER.

- POTATOS LOADER

- CARROT HARVESTER

- ONION LOADER

- CITRUS HARVESTER

- DISPOSABLE PLASTIC BOX..

- VEGETABLE HARVESTER DI PIETRI

- VEGETABLE HARVESTERS ORTOMEC

- VEGETABLES HARVESTER

- GARLIC CULTURE

- PLASTIC DISPENSERS MACHINE

- SOIL DISINFECTION BY STEAM

- FURROW OPENER

- KITAPE

- FLAME WEEDING

- MULTIFRAS

- POTATO PLANTER

- PRE-BED FORMER

- MACHINE FOR COLLECTION IRRIGATION HOSE

- RECOLHEDORA DE PLÁSTICO AGRICOLA

- AUTOMATIC HOE

- WEEDING MACHINES

- SYSTEM FOR COLLECTING PARSLEY.

- TRANSPLANTERS

- SIDE CONVEYOR BELT

- MOBILIZATION OF SOIL

- LIVESTOCK

- POLISHER

- SPRAYERS

- SOWING

-

FORESTRY

- ANGLODOZERS

- GARDEN VACUUM CLEANERS

- HEDGE MOWING BAR

- BIOSHREDDERS

- BULDOZERS

- HYDRAULIC HEADS

- ROTARY CUTTERS

- LAWN MOWER

- BULLRING CUTTER

- TRIMMER

- FURROW OPENER RIENFORCED.

- MOUND MACHINE FOR ORCHARDS.

- DISC HARROWS V-TYPE

- FORESTRY WINCHES

- POST HOLE DIGGER

- TOOL HOLDERS ER

- SHOVEL GRADERS

- PRUNERS FOR ORCHARDS

- RIPPERS

- BRUSH CUTTERS

- WOOD-SPLITTERS

- BLADE ROLLER.

- ROTARY TILLERS BY RADIO CONTROL

- HYDRAULIC ARM IRONER

- TRACTOR BACKHOE

- SHREDDERS AGRIMASTER

- ROTARY TILLERS JOPER.

- FORESTRY SHREDDERS

- CRUSHERS RINIERI

- ROTARY TILLERS HERKULIS

- CRUSHERS FOR BIOMASS

- STONE MILLS

- STRAINERS SERRAT LATERALS

- VINEYARDS REMAINS FROM PRUNING

- CRUSHERS SERRAT

- IRRIGATION SYSTEMS

- AGRO CONTROL SYSTEMS

- SCISSORS FOR PRUNING.

- TRANSPORT

- FLORICULTURAL NURSING

-

GRAPE VINE

- BOXES STAINLESS FOR GRAPE

- PLASTIC BOXES STACKABLE

- ELECTRICAL TROLLEY

- WIRE UNWINDERS

- FEEDING BUCKET

- MANURE SPREADERS

- VINEYARD DISC HARROWS

- OFFSET MACHINERY

- ELECTRIC TYING MACHINE FOR GRAPEVINE

- HITTING STAKES HAMMER

- POST HOLE DIGGER.

- ROLLER HARROW VINEYARD

- TOWING OF INOX FOR GRAPE.

- SCISSORS FOR PRUNING

- VINE AND TREES PLANTER

- TOWED VINDILLER

- PRUNING REST CRUSHER

- CHISEL VINHATEIRO

- USED MACHINES

- SPARE PARTS

- ABBRIATA

- ABRIMEC

- AGRATOR

- AGRICOLA ITALIANA

- AGRIMASTER

- AGROBIOFILM

- AGROGUIA

- AGROOP

- AGROTECH

- AMB ROUSSET

- ARGILES

- ASPLA

- BARGAM

- BBKW

- BONDIOLI & PAVESI

- BONINO

- CACHAPUZ

- CAEB

- CARLOTTI G. & C. S.N.C.

- CECCATO OLINDO

- CETAP

- CHECCHI & MAGLI

- CITERGAZ

- COMEB

- D'EUSANIO

- DAGNAUD

- DI PIETRI

- DONDI

- EAZYCUT

- ENOROSSI

- ENRIA

- F. LLi. ANNOVI

- FAE

- FARDIN

- FELCO

- FERRARI

- FEUCHT - OBSTTECHNIK

- FIALHO

- FIMAKS

- FMP

- Farmi

- GARRIGA

- GASPARDO

- GIAMPI

- GREEN-TECHNIK

- HERKULIS

- HYMACH

- ID-DAVID

- IMAC

- J.J.BROCH

- JB INDUSTRIE

- JOPER

- M.MARTI

- MAIA

- MAMMUT

- MARTIGNANI

- MM SPRAY

- MOSA GREEN

- MTS.SANDEI

- NASI

- OLITREE

- OLIVERAGRO

- OMARV

- ORTOMEC

- PAGLIARI

- PELLENC

- PIRODISERBO

- PIUSI

- POMI

- PREMIER TECH

- R.A.P

- REBOAL

- RIBATEJO

- RINIERI

- ROCHE

- SERRAT

- SIMON

- SIMOX

- TAREX

- TATU

- TERRADONIS

- TERRATECK

- TEYME

- TOMENZOLI

- TOMIX

- TOUPEIRA

- TRIMBLE

- VALENTINI

- WAGNER

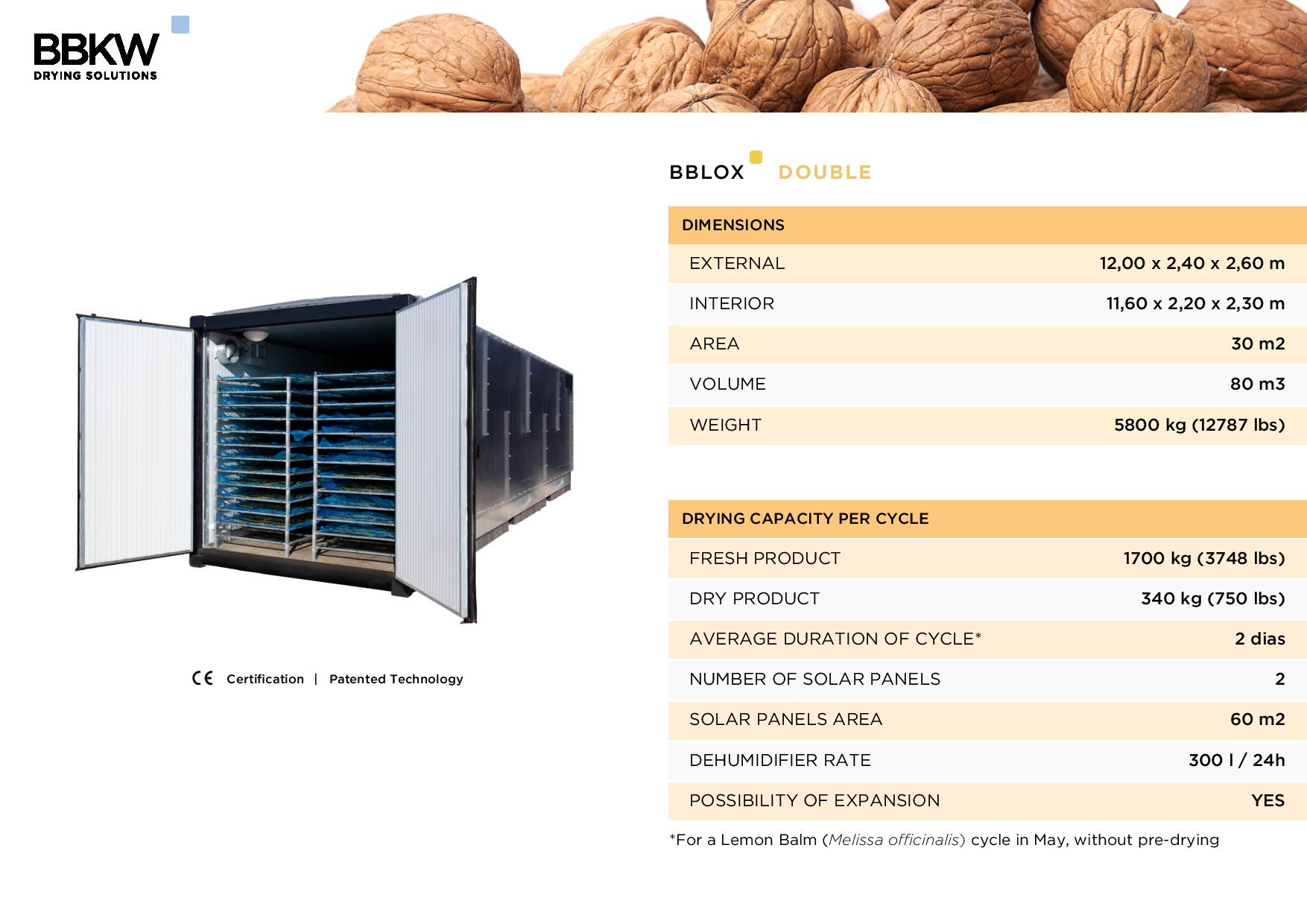

HYBRID SOLAR DRYER - AROMATICS AND FOOD - BBKW DOUBLE

Price

Query

(VAT 13% not included)

-

Categories::

-

Brands:BBKW

- Available by order

-

SKU::BBLOX - 19951167

-

PDF catalog:657_20200504010619_pdf_products.pdf

Observation:

Transport not included

Assembly, start-up and training of operators carried out

by specialized technicians not included in the price

Delivery time: to inform

12 month warranty against possible manufacturing defects

Electric working voltage: 380 V / 220 V

Transport not included

Assembly, start-up and training of operators carried out

by specialized technicians not included in the price

Delivery time: to inform

12 month warranty against possible manufacturing defects

Electric working voltage: 380 V / 220 V

HYBRID SOLAR DRYER - AROMATICS AND FOOD - BBKW DOUBLE

The standard module consists in a metal structure coated by steel panels with 3 mm of thickness, followed by isothermal panels with 30 mm.

SOLAR COLLECTORS

Made in polycarbonate, with calibrated temperature and humidity sensors.

AIR FORCING

The intake and exhaust air in the drying chamber is processed through ventilation ducts, equipped at the end with 3 motorized flow registers and 2 axial centrifugal extractors.

2 x Extractor – Volume flow rate 990 m 3 / h and maximum power of 110 W

3 x Damper actuators for intake air – power 1,5 W

3 x Temperature and Humidity sensors

12 x Fans – Helical fans with maximum power of 120 W each

DEHUMIDIFICATION AND HEATING

Condensing dehumidifier with extractive capacity of 150 l water/day and volume flow rate of 1000 m3 /h. Variable power heaters: 650, 1500, or 2000 W and a volume flow rate of 186 m3 /h.

INFORMATIC MODULE

1 x Electric switchboard in a IP65 box with:

Processor with web server acting on 2 modules of activation of relays (capacity of actuation up to 12 devices)

2 x Dehumidifier

2 x Heater

1 x Auxiliary equipment (fan or another) + jack

3 x Damper actuator (for ceiling and side panel and extractor)

3 x Exhaust actuator

3 x Temperature and relative humidity sensors (for ceiling and side panel and inner chamber)

COMMUNICATION

SIM slot for data card of any mobile operator

Ethernet rj45 slot

DRYING EQUIPMENT (OPTIONAL)

Drying tables - Removable and stackable trays with galvanized metal frame and double plastic mesh base.

Dimensions: 2,00 × 0,95 m (feet 12 cm). - Up to 120 per dryer

Ventilated trolley – Improving air circulation of drying tables. Its use reduces drying time up to 30% less, improving the product qualit. - Up to 8 per dryer

Ventiladed boxes - Boxes with wheels allowing easy movement. They are upwardly ventilated, provide faster drying and substantially reduce labor. They can be mechanically loaded and unloaded outside the dryer.

Dimensions: 1,5 × 1,5 × 1,5 m – Up to 6 per dryer

Consult the optional equipment in the online store

The website uses cookies to ensure you get the best experience on our website.